How to Navigate the Process of Flex PCB Assembly for Your Projects

In the rapidly evolving landscape of electronics, "flex PCB assembly" has emerged as a pivotal process for engineers and designers looking to create compact, lightweight, and efficient circuits. This guide aims to unravel the complexities surrounding the assembly of flexible printed circuit boards, offering insights and practical steps to successfully navigate the entire process. From understanding the unique properties of flex PCBs to selecting the right materials and techniques, we will cover essential considerations that every project should address. Whether you're a seasoned professional or a beginner venturing into the world of flexible electronics, this comprehensive outline will equip you with the knowledge necessary to optimize your flex PCB assembly projects, ensuring that your designs meet both functionality and reliability standards. Prepare to enhance your skills and elevate your projects to new heights through the mastery of flex PCB assembly.

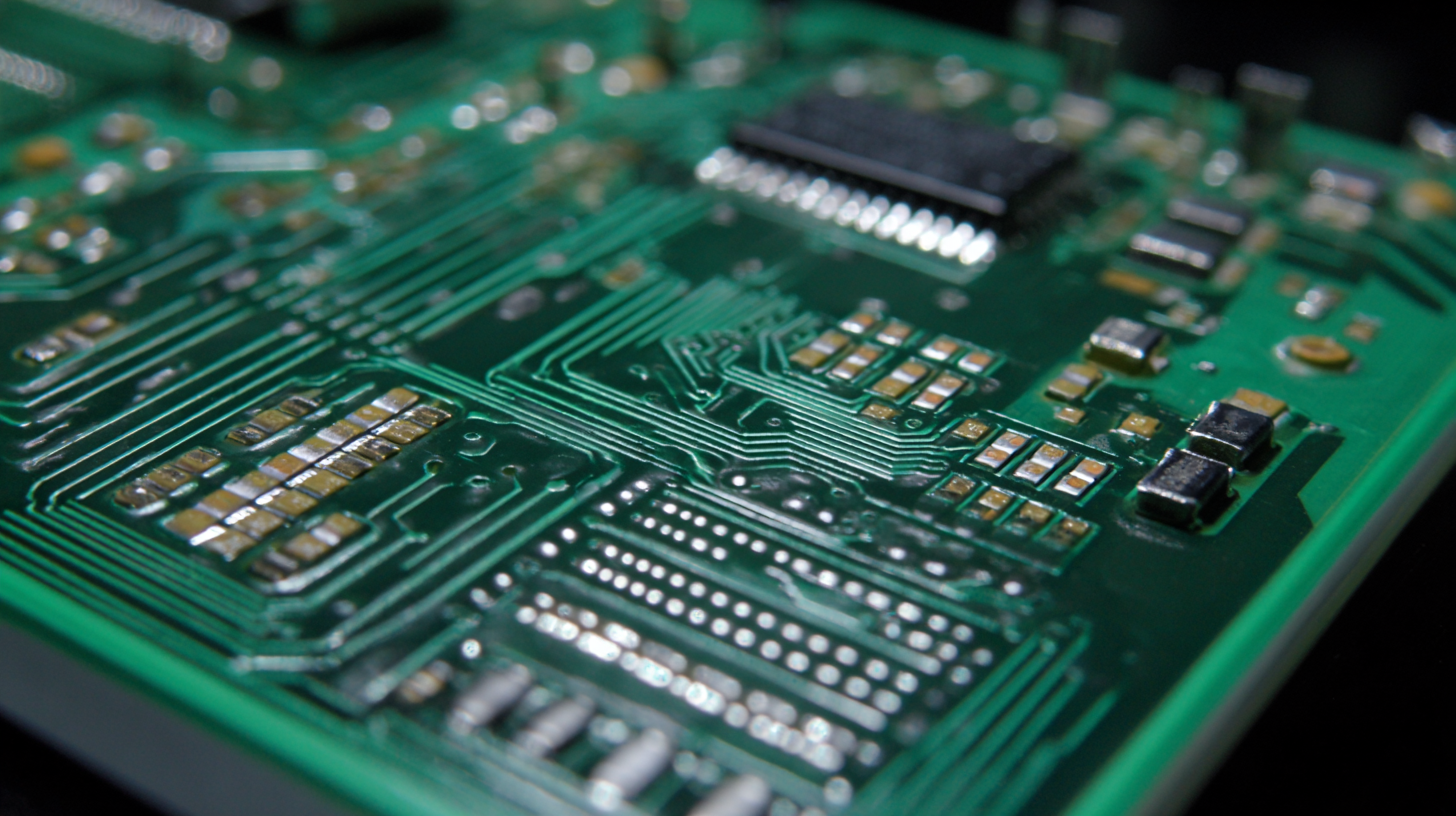

Understanding the Basics of Flex PCB Technology for Effective Project Planning

Flex PCB technology is revolutionizing the electronics industry by offering innovative solutions for complex project needs. Understanding its fundamentals is essential for effective project planning. Flex PCBs, characterized by their lightweight and adaptable nature, allow for intricate designs that traditional rigid boards cannot accommodate. They enable flexibility in product design, making them ideal for compact and portable electronics, such as smartphones and wearable devices. Additionally, they provide reliable performance even in tightly constrained spaces, reducing the risk of failure during operation.

When planning a project involving flex PCBs, it is crucial to consider the unique manufacturing processes and material specifications. Familiarize yourself with various substrate materials, such as polyimide or polyester, and their thermal properties. Moreover, understanding the routing techniques and assembly methods, including the use of adhesives or soldering processes, will significantly impact the final product’s quality and reliability. By taking these key aspects into account during the planning phase, you can streamline the assembly process and ensure that the final design meets the desired performance standards, ultimately leading to a successful project outcome.

Flex PCB Assembly Process Overview

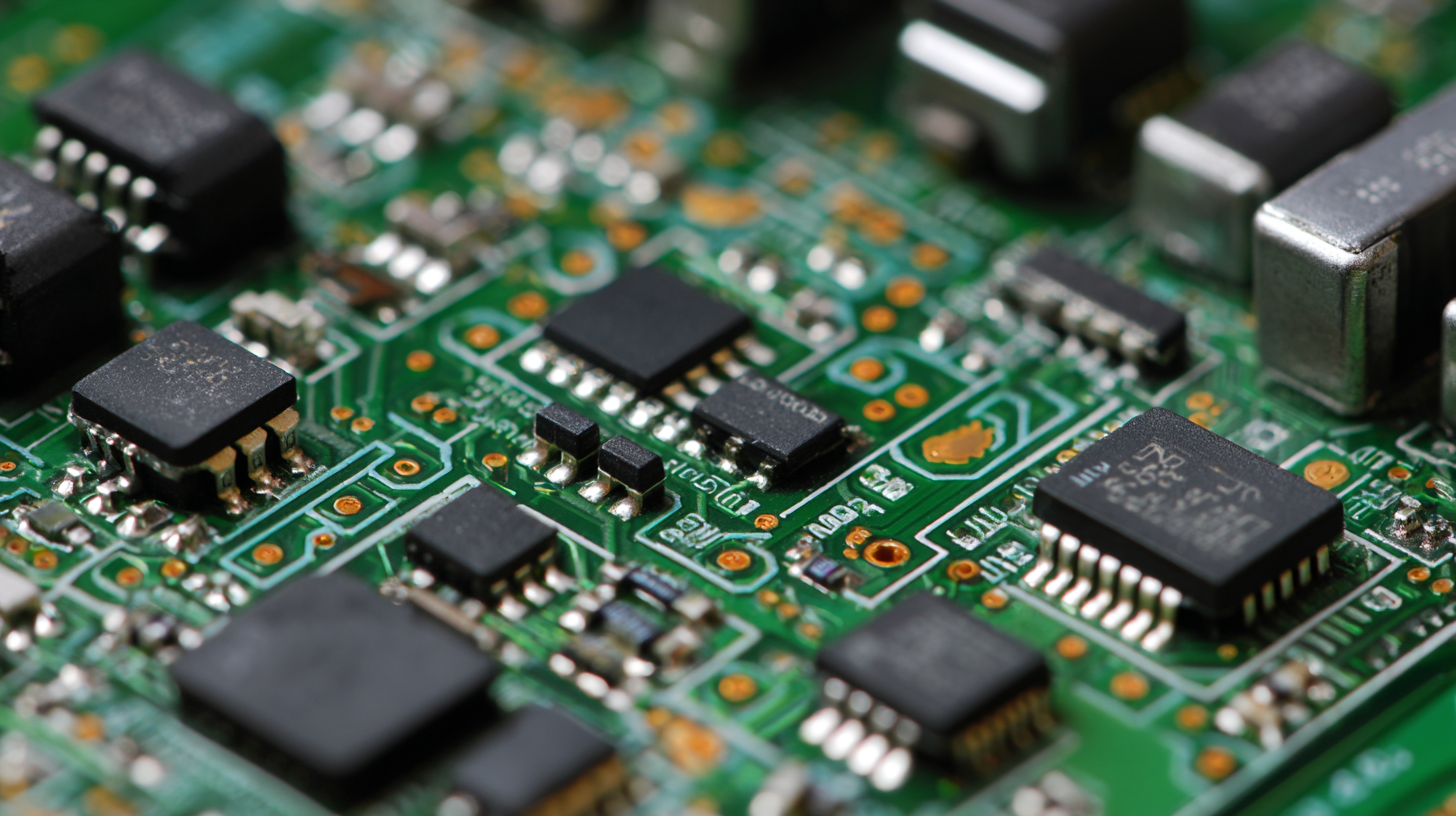

Key Considerations for Designing Flex PCBs for Assembly Efficiency

When designing flex PCBs for optimal assembly efficiency, several key considerations come into play. First and foremost, it's essential to focus on the layout. Effective use of space can significantly reduce manufacturing costs and enhance performance. Designers should prioritize the placement of components, ensuring that they minimize the distance between similar parts and utilize the flexible nature of PCBs to avoid unnecessary bends and stress, which could lead to failures during assembly.

Moreover, material selection is crucial in enhancing assembly processes. Choosing the right substrates and adhesives can influence the durability and flexibility of the PCB. Designers should also consider the compatibility of materials with various soldering techniques. A thorough understanding of thermal properties and how they affect soldering will allow for better joint integrity and reduced defects. Additionally, integrating test points within the PCB design can facilitate easier debugging and enhance the overall reliability of the assembly process, thereby contributing to a smoother transition from design to production.

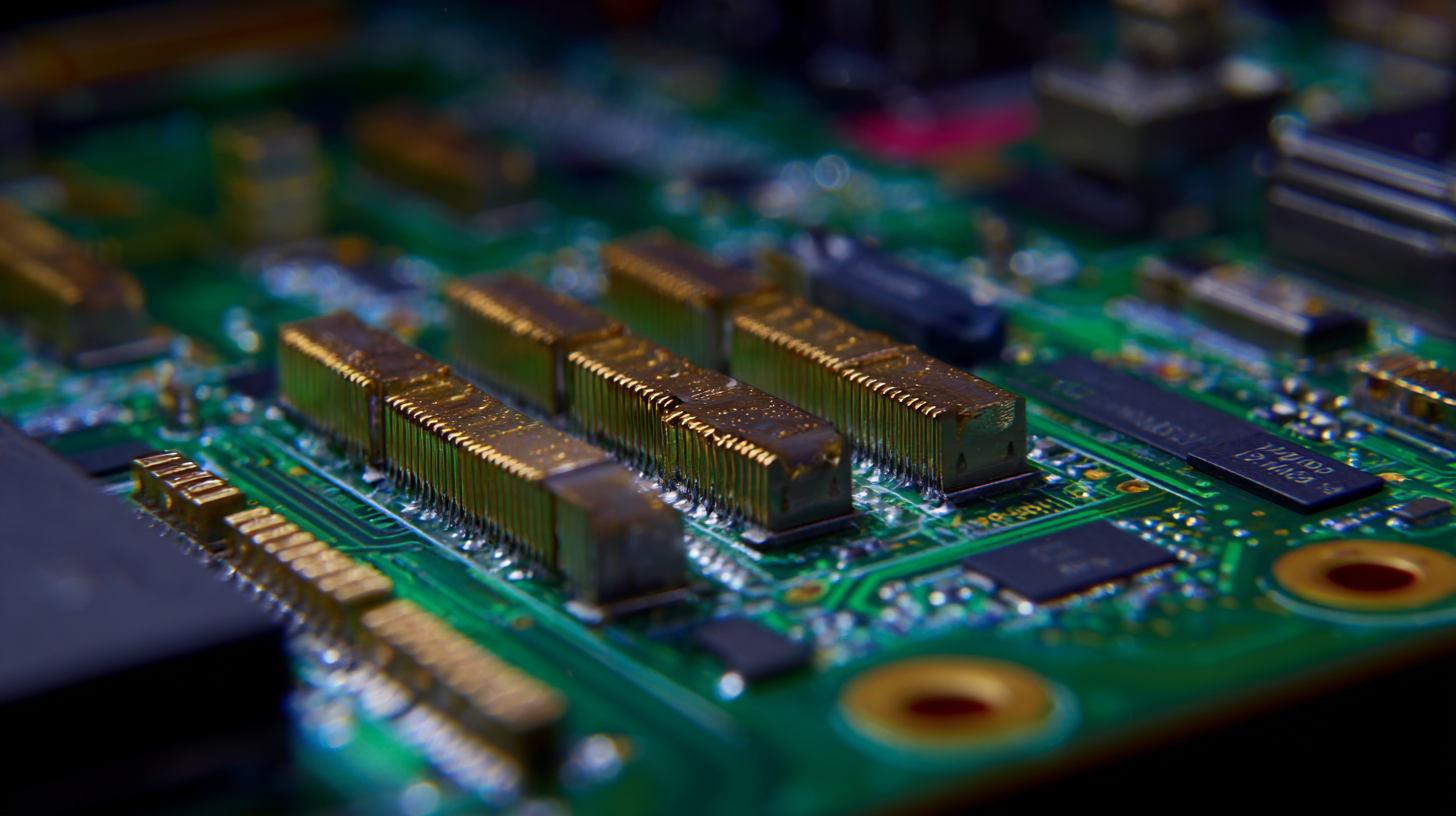

Step-by-Step Guide to Sourcing Materials for Flex PCB Assembly

When initiating a flex PCB assembly project, sourcing the right materials is crucial for ensuring reliability and performance. Start by identifying the specific requirements of your project, such as the type of flex circuits needed, the desired thickness, and the operating environment. Research different manufacturers that offer flexible substrates like polyimide or polyester, and compare their specifications to find a suitable option that aligns with your technical needs.

Next, prioritize sourcing quality components that can withstand the unique stresses imposed on flex PCBs. Search for reputable suppliers of connectors, vias, and adhesive materials that are designed for flexible applications. It’s essential to check certifications and test reports for the components to ensure they meet industry standards. Additionally, consider engaging with suppliers that provide value-added services, such as design support or assembly services, to streamline the sourcing process and improve the overall efficiency of your project. By following these steps, you can effectively navigate the material sourcing phase of your flex PCB assembly.

Best Practices for Managing the Flex PCB Assembly Process

Managing the flex PCB assembly process is vital for ensuring the success of your electronic projects. According to the IPC (Association Connecting Electronics Industries), the flex PCB market is projected to grow by 8.5% CAGR from 2021 to 2026, highlighting its increasing relevance in sectors like automotive and medical devices. To effectively navigate this process, it’s crucial to adopt best practices that enhance efficiency and product reliability.

One key practice is to utilize advanced CAD software for designing your flex PCBs. This technology not only helps in visualizing the assembly process but also minimizes design errors. As reported by the research firm TechNavio, manufacturers that leverage such software can reduce the design cycle time by up to 30%. Additionally, maintaining clear communication with your assembly partner ensures that all specifications are met and minimizes costly revisions.

Tip: Always conduct a thorough materials assessment before beginning assembly to ensure compatibility with your design requirements. Additionally, implementing regular quality checks throughout production can help identify issues early, saving both time and resources. By following these best practices, you can streamline the flex PCB assembly process, ultimately leading to a more successful project outcome.

Common Challenges in Flex PCB Assembly and How to Overcome Them

When navigating the process of flex PCB assembly, several common challenges can arise that may impact the quality and efficiency of your projects. One significant challenge is the handling and processing of flexible materials, which are more susceptible to damage compared to rigid boards. According to a report by IPC (Institute of Printed Circuits), improper handling can lead to a 30% increase in rework, significantly impacting project timelines and costs. To mitigate this, investing in specialized training for personnel and using tools designed for flexible circuit assembly can prove essential.

When navigating the process of flex PCB assembly, several common challenges can arise that may impact the quality and efficiency of your projects. One significant challenge is the handling and processing of flexible materials, which are more susceptible to damage compared to rigid boards. According to a report by IPC (Institute of Printed Circuits), improper handling can lead to a 30% increase in rework, significantly impacting project timelines and costs. To mitigate this, investing in specialized training for personnel and using tools designed for flexible circuit assembly can prove essential.

Another challenge often faced is the precise alignment of components on a flexible substrate. Flex PCBs can have intricate designs with components placed very close together. As highlighted in a recent study by Research and Markets, inaccuracies in placement can result in defects that might reach up to 20% in poorly managed assembly lines. Utilizing advanced printing techniques and automated assembly systems can help in achieving higher accuracy, with some companies reporting up to 50% reductions in defects through these methods. Therefore, addressing these challenges through training and technology adaptation can greatly enhance the success of flex PCB projects.