How to Optimize Your Flexible Printed Circuit Board Production for Maximum Efficiency and Cost Savings

The increasing demand for flexible printed circuit boards (FPCBs) across various industries has highlighted the need for optimizing production processes to enhance efficiency and reduce costs.

According to a recent report by Research and Markets, the global flexible printed circuit board market is projected to reach $55.3 billion by 2025, growing at a CAGR of 12.1% from 2020.

This growth is driven by advancements in consumer electronics, medical devices, and automotive applications.

However, achieving maximum efficiency in FPCB production requires a comprehensive understanding of design, material selection, and manufacturing techniques.

In this guide, we will explore strategies to streamline your flexible printed circuit board production, ensuring that your operations not only meet the rising demands of the market but also contribute to significant cost savings.

Strategies for Reducing Waste in Flexible Printed Circuit Board Manufacturing

In the rapidly evolving landscape of flexible printed circuit board (FPCB) manufacturing, optimizing production processes is essential for maximizing efficiency and achieving significant cost savings. A key strategy for reducing waste in FPCB manufacturing is implementing advanced direct imaging systems. According to industry reports, the direct imaging system market is expected to grow at a CAGR of 9%, primarily driven by advancements in printed circuit board (PCB) technology. In 2024, the PCB segment is projected to hold over 38.6% of the market share, underscoring its importance in reducing manufacturing waste and enhancing precision.

Additionally, the integration of 3D-printed electronics is emerging as a game-changer, with projections indicating that this market will reach substantial figures by 2026. Embracing these technologies allows manufacturers to not only trim excess materials but also streamline production timelines, ultimately translating into cost reductions. Focusing on these innovative strategies is imperative for manufacturers seeking to remain competitive in an industry characterized by rapid technological advancements and increasing demand for efficiency.

Implementing Automation to Enhance Production Speed and Precision

The integration of automation in flexible printed circuit board (FPCB) production significantly enhances both production speed and precision, offering manufacturers a competitive edge. According to a recent report by Allied Market Research, the global FPCB market is projected to reach $38.02 billion by 2025, driven largely by the increasing demand for automated solutions. Automation reduces manual intervention, which not only accelerates the manufacturing process but also minimizes the risk of human error. For instance, automated pick-and-place machines can increase component placement accuracy to over 99.9%, a critical factor in high-density circuit applications.

Furthermore, adopting automated inspection systems can lead to a significant reduction in defect rates. Industry data indicates that automated optical inspection (AOI) can increase defect detection rates by as much as 90%, compared to manual inspection processes. This level of precision not only enhances product quality but also reduces costly rework and material waste, contributing to overall cost savings. By leveraging advanced automation technologies, manufacturers of FPCBs can optimize their production workflows, fostering an environment where efficiency and quality are paramount. The shift towards automation is not merely a trend but a necessary evolution in staying relevant in the rapidly expanding electronics market.

Choosing the Right Materials for Cost-Effective FPCB Production

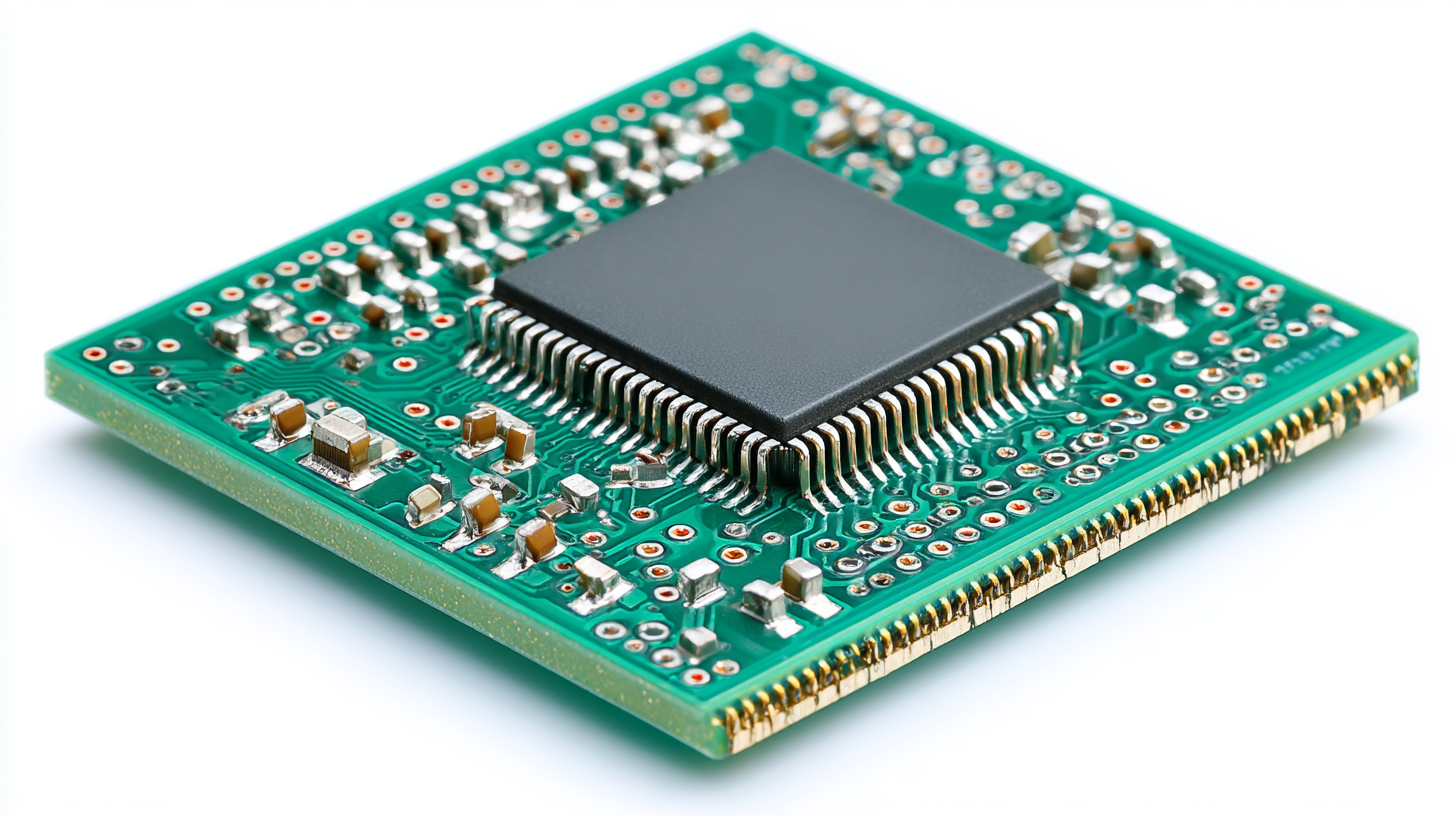

When it comes to achieving maximum efficiency in flexible printed circuit board (FPCB) production, the choice of materials plays a pivotal role. Selecting the right substrates, conductors, and adhesives can significantly influence the overall performance and cost of the final product. Materials such as polyimide and polyester are popular choices for substrates due to their excellent thermal performance and flexibility. They not only ensure durability but also allow for intricate designs that modern electronics demand.

In addition to substrates, the choice of conductive materials is crucial. Copper remains a top choice due to its excellent electrical conductivity and reliability. However, alternative materials like silver or specialized conductive inks can be considered for specific applications where cost savings are essential. Additionally, the use of low-cost adhesives can optimize the bonding process, further reducing production expenses while maintaining high product quality. By carefully selecting these materials, manufacturers can enhance their production efficiency, reduce waste, and ultimately achieve significant cost savings in the FPCB production process.

FPCB Production Cost Analysis

Best Practices for Quality Control in Flexible Printed Circuit Board Processes

Quality control is paramount in the production of flexible printed circuit boards (FPCs) to ensure their efficiency and reliability. Implementing best practices can significantly reduce defects and enhance the overall manufacturing process. Advanced techniques such as AI-driven quality inspection and mathematical modeling of circuit configuration can play a crucial role in identifying potential defects early in the production line. For instance, using deep neural networks to detect soldering splashes or other anomalies can drastically improve the production yield and reduce costs.

Additionally, methodologies like Flying Probe Testing allow for rapid and accurate testing of PCB assemblies without the need for traditional fixtures, thereby saving time and resources. As FPC technology evolves, integrating intelligent production processes and quality strategies not only helps in optimizing efficiency but also supports sustainability efforts, especially in the context of recyclability. The focus on creating body-conformable electronics through advanced fabrication techniques further emphasizes the importance of maintaining high-quality standards to meet the increasing demands of the wearable technology market. By prioritizing quality control throughout the production process, manufacturers can achieve maximum efficiency and cost savings while delivering reliable electronic solutions.

Leveraging Design Software to Streamline FPCB Development and Production

The growing demand for risk reduction in flexible printed circuit board (FPCB) production necessitates effective manufacturing decisions that can accelerate market growth. Recent industry reports indicate that using design software, particularly simulation tools, allows manufacturers to assess and mitigate risks associated with complex systems and processes early in the development cycle. By employing advanced digital twin technology, companies are able to create virtual replicas of products and assets, significantly speeding up development times and optimizing both product performance and production processes.

In the context of FPCB production, leveraging such design software not only streamlines workflow but also enhances innovation and cost-effectiveness. For instance, studies show that manufacturers who integrate simulation software can reduce prototyping costs by up to 30%, allowing them to allocate resources more efficiently. Additionally, digital twins facilitate continuous improvement through real-time data analysis, ultimately leading to higher quality outputs and reduced operational costs. As the industry increasingly moves toward digital transformation, the adoption of these tools is essential for staying competitive in a rapidly evolving market.

How to Optimize Your Flexible Printed Circuit Board Production for Maximum Efficiency and Cost Savings

| Parameter |

Current Value |

Target Value |

Impact |

| Yield Rate (%) |

85 |

95 |

Increase profitability |

| Production Time (days) |

30 |

20 |

Reduce lead time |

| Material Cost ($ per unit) |

10 |

8 |

Lower production costs |

| Design Iterations (average) |

5 |

3 |

Streamline design process |

| Employee Hours (per project) |

200 |

150 |

Increase efficiency |