2026 How to Choose the Best Butterfly Valves for Sale?

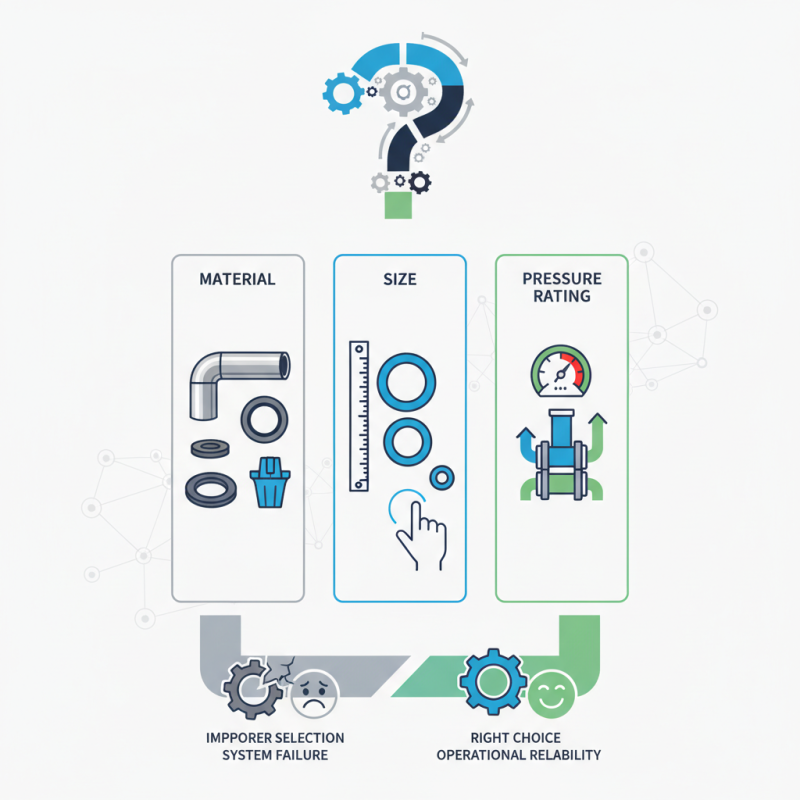

Choosing the right butterfly valves for sale is crucial for efficiency in various industries. A recent report from the American Society of Mechanical Engineers highlights that improper valve selection can lead to system failures, costing companies thousands in repairs. John Smith, an industry expert at Valve Solutions Inc., emphasizes, “The right valve choice can significantly improve operational reliability.”

Butterfly valves are popular for their compact design and ease of use. Many industries, such as water treatment and chemical processing, rely heavily on these valves. In 2022, sales in the butterfly valve market reached $1.5 billion, according to Global Market Insights. However, not all products are created equal. Many users struggle to identify the best options among butterfly valves for sale.

It is essential to consider factors like material, size, and pressure rating before making a purchase. Some products may not perform well under extreme conditions. Recognizing these shortcomings is critical for preventing unexpected downtime. A hasty decision could lead to significant operational issues. Knowing what to look for can make all the difference in valve performance and longevity.

Understanding Butterfly Valves: Types and Applications

Butterfly valves play a vital role in various industries. They are known for their simple design and versatility. The two main types are lug-style and wafer-style valves. Lug-style valves are often used in dead-end service. Wafer-style valves are more suited for standard connections. Each type serves unique applications depending on specific needs.

According to industry reports, the global butterfly valve market is expected to reach USD 6.5 billion by 2026. This growth reflects increasing demand in water treatment, oil and gas, and chemical processing. For instance, in water distribution, these valves allow for efficient flow control. In the oil and gas sector, they excel in high-pressure applications. However, the choice of materials affects their lifespan and performance. Stainless steel, ductile iron, and plastic are commonly used, yet each has pros and cons.

Understanding the specific application is crucial. Some valves may not perform optimally in extreme conditions. For example, high temperatures and corrosive environments can lead to failure. Regular maintenance is often overlooked but critical to valve longevity. Users should regularly inspect their butterfly valves to ensure reliability.

Key Factors to Consider When Choosing Butterfly Valves

When choosing butterfly valves, several key factors warrant your attention. Material is crucial—determine whether stainless steel, plastic, or cast iron suits your application best. Each material has unique advantages and limitations. The size of the valve should match the pipe diameter. Oversized or undersized valves can lead to inefficiencies.

Next, consider the pressure rating. The valve must withstand the system's operating pressure without compromising performance. Actuation type also plays a significant role; manual, electric, or pneumatic options are available. Think about how often you'll need to operate the valve.

Lastly, pay attention to the design features. Some valves offer better sealing capabilities or lower torque requirements. Perhaps you might overlook important details such as maintenance needs. Regular checks can prevent costly repairs. Reflecting on these factors ensures a more informed decision when purchasing butterfly valves.

2026 How to Choose the Best Butterfly Valves for Sale? - Key Factors to Consider When Choosing Butterfly Valves

| Key Factor | Description | Importance Level | Common Materials |

| Size | Determines the flow capacity and installation requirements. | High | Cast Iron, Stainless Steel |

| Pressure Rating | Indicates the maximum pressure the valve can handle. | High | PVC, Metal Alloys |

| Temperature Range | Ensures the valve operates reliably under specific temperature conditions. | Medium | Teflon, High-Temperature Alloys |

| Seat Material | Affects sealing performance and chemical resistance. | High | EPDM, Nitrile |

| Actuation Type | Determines how the valve is opened and closed (manual, pneumatic, electrical). | Medium | Manual, Electric Actuator |

Materials and Construction: Impact on Valve Performance

When selecting butterfly valves, the choice of materials is crucial. The materials impact not just durability, but also performance. Common materials include stainless steel, ductile iron, and PVC. Each has its own advantages and drawbacks. Stainless steel is strong but may corrode in certain environments. PVC is lightweight but less suitable for high-pressure applications.

Construction plays a significant role as well. The design affects flow capacity and sealing. A poorly constructed valve can lead to leaks or operational failures. Pay attention to features like the type of seat used and construction quality. Sometimes, cheaper options can result in costly repairs later.

Consider the specifications carefully. Assess the operating temperature and pressure ratings. This ensures the valve will function as needed. In some cases, a valve may look good but underperform due to material choices. Always reflect on long-term impacts. Investing time in research can prevent future headaches.

2026 How to Choose the Best Butterfly Valves for Sale? - Materials and Construction: Impact on Valve Performance

Comparison of Brands: Finding Reliable Butterfly Valves for Sale

When searching for reliable butterfly valves for sale, brand comparison is essential. The market is robust, reflecting diverse needs. Research shows that the global butterfly valve market surpasses $6 billion, with a steady growth rate of 5% annually. This indicates an increasing demand for high-quality valves in various industries.

Choosing the right supplier can be daunting. Many manufacturers highlight durability and performance. However, not all products are equal. A recent industry report noted that 40% of buyers experienced issues within the first year due to subpar materials. Ensure you examine warranties and service records. Look for feedback from previous customers, as personal experiences often reveal the truth behind the brand.

Some brands may offer appealing prices but compromise on quality. Buyers should balance cost with reliability. It's crucial to consider certifications and material specifications. High-grade materials prevent leaks and extend the product lifespan. Common standards include API and ANSI certifications, which provide a safety net against inferior products. An informed decision relies on thorough research and understanding your unique operational needs.

Installation and Maintenance Tips for Butterfly Valves

When installing butterfly valves, ensure the surrounding area is clean. Dirt or debris can cause improper sealing. The valve should be mounted between flanges. Misalignment might lead to leaks. According to industry reports, improper installation can reduce valve lifespan by up to 30%.

Regular maintenance is crucial. Inspect for wear and corrosion every six months. Lubricate the stem regularly to prevent seizing. Inadequate lubrication can double the chance of failure. Additionally, operators should exercise caution during operation. A quick check can save future headaches.

Remember, not all valves are designed equally. Choosing the right materials is crucial based on the application. Sometimes, a valve may look fine but have internal damage. This can lead to unexpected failures. Investing in quality inspection tools is a wise choice.