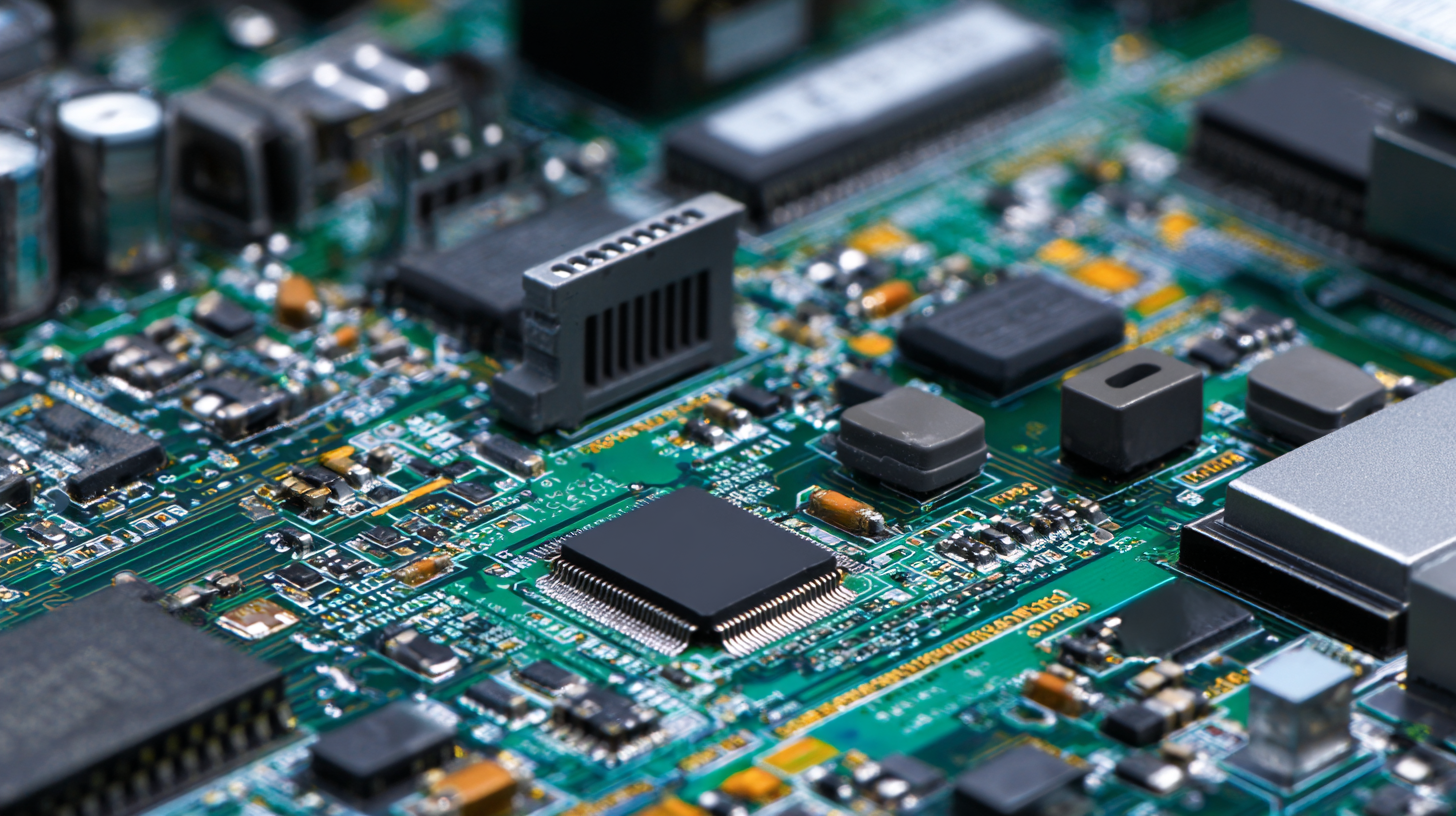

Excellence in Manufacturing from China Delivering Global Solutions for Best Flex PCB Assembly

In an era where innovation and efficiency are paramount, excellence in manufacturing from China has emerged as a cornerstone for delivering global solutions, particularly in the realm of flex PCB assembly. As the electronics industry continues to evolve, the demand for flexible printed circuit boards (PCBs) has surged, driven by the need for lightweight, compact, and high-performance devices that can meet the rigorous requirements of modern applications. This blog delves into the unique capabilities and competitive advantages that Chinese manufacturers bring to the table, showcasing exemplary case studies that highlight their expertise in flex PCB assembly. By examining different examples, we will explore how these manufacturers not only enhance production processes but also contribute to sustainable practices, ultimately shaping the future of electronics on a global scale.

Understanding the Characteristics and Applications of Different Flex PCB Types

Flex PCBs have emerged as a pivotal component in the rapidly evolving automotive industry, driven by the dual forces of electrification and connectivity. With the global automotive PCB market projected to grow from $9.15 billion in 2023 to $15.1 billion by 2032, the importance of flexible printed circuit boards in this sector cannot be overstated. Flex PCBs, known for their lightweight and adaptable nature, allow for innovative designs that are critical for the advanced electronics found in modern vehicles.

Different types of flex PCBs cater to varying applications, from single-sided circuits ideal for basic functionalities to multilayer options that support complex systems. With the market for single-sided flex PCBs expected to reach $1.92 billion by 2025, and an anticipated CAGR of 4.5% leading to $2.73 billion by 2033, it's clear that these flexible solutions are gaining traction. As manufacturers in China focus on delivering high-quality flex PCB assemblies, they are not only meeting local demands but also providing global solutions that drive efficiency and innovation in automotive electronics.

Best Practices for Selecting Flex PCBs Based on Product Requirements

When selecting flex PCBs for your specific product requirements, it’s essential to consider several key factors to ensure performance and reliability. First, evaluate the intended application of the PCB. Understanding the environment in which the flex PCB will operate—be it high temperatures, humidity, or mechanical stress—will guide your material choice and design specifications.

Tip: Always prioritize flexibility and bend radius when choosing your PCB. Different applications may require different flexibilities; for instance, wearable technology demands tighter bends, while automotive applications may require broader flex designs to accommodate larger components.

Another vital aspect is the thickness of the substrate and copper layers. Thinner materials can lead to more complex designs, allowing for intricate circuitry that saves space. However, ensure that the thickness matches your product requirements to avoid reliability issues over time.

Tip: Perform thorough testing with prototypes. This step will help identify any potential weaknesses in the design before mass production, allowing adjustments to be made and increasing the overall success of your product.

Excellence in Manufacturing from China Delivering Global Solutions for Best Flex PCB Assembly - Best Practices for Selecting Flex PCBs Based on Product Requirements

| Dimension |

Value |

| Minimum Bend Radius |

0.5 mm |

| Thickness Options |

0.1 - 0.5 mm |

| Layer Count |

1 - 6 Layers |

| Material Used |

Polyimide, FR-4 |

| Surface Finish Options |

HASL, OSP, ENIG |

| Max Operating Temperature |

130°C |

| Minimum Trace Width |

0.1 mm |

| Total Cost Estimation |

$500 - $5000 |

How to Optimize Flex PCB Assembly for Enhanced Performance

In today's rapidly evolving electronics landscape, optimizing flex PCB assembly is essential for achieving enhanced performance and reliability. Flex PCBs, known for their lightweight and adaptable nature, offer unique advantages in applications ranging from consumer electronics to automotive systems. To fully harness these benefits, manufacturers must focus on precision in design and assembly processes. Utilizing advanced techniques such as automated pick-and-place and precise soldering methods can significantly reduce assembly time and improve the overall quality of the final product.

Another critical aspect of optimizing flex PCB assembly is selecting the right materials. High-quality substrates and components can dramatically affect the performance and durability of the circuits. By investing in the latest materials technology, manufacturers can create PCBs that endure rigorous mechanical stresses while maintaining electrical integrity. Additionally, incorporating simulation tools during the design phase can help identify potential issues early, allowing for adjustments that enhance functionality before production even begins. Embracing these strategies not only improves the efficiency of the assembly process but also ensures that the finished product meets the increasing demands of global markets.

Performance Metrics of Flex PCB Assembly Optimization

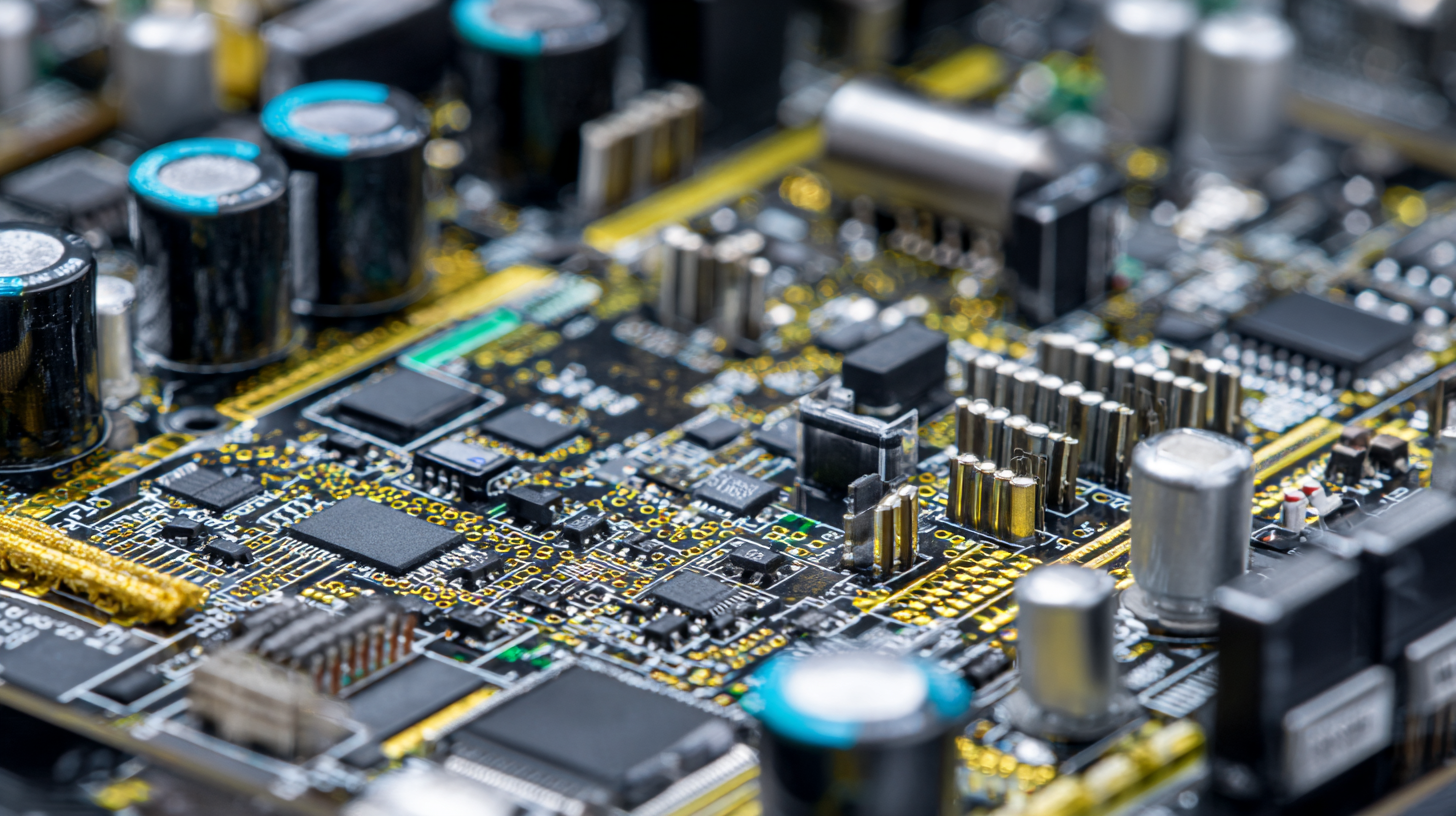

Innovative Solutions in Flex PCB Manufacturing: Key Features and Technologies

In the rapidly evolving landscape of electronics, flexible printed circuit boards (Flex PCBs) are emerging as pivotal components in a variety of applications, ranging from consumer electronics to medical devices. According to a recent report by Allied Market Research, the global flexible printed circuit board market is projected to reach $36.36 billion by 2027, growing at a CAGR of 10.8% from 2020. This surge is attributed to the increasing demand for miniaturization and lightweight components in consumer electronics, where Flex PCBs play a critical role due to their lightweight and versatile characteristics.

Innovative solutions in Flex PCB manufacturing focus on advanced technologies, such as the adoption of high-density interconnect (HDI) processes and sophisticated materials that enhance durability and performance. Notably, the integration of techniques like laser drilling and roll-to-roll processing are revolutionizing the production efficiency and cost-effectiveness of Flex PCBs. The implementation of these technologies has enabled manufacturers in China, which accounts for over 30% of the global Flex PCB production, to deliver products that not only meet stringent quality standards but also ensure high reliability under varying environmental conditions. This commitment to excellence in manufacturing is crucial for companies seeking comprehensive global solutions in the ever-competitive electronics market.

Case Studies: Successful Global Implementations of Flex PCB Assemblies in Various Industries

In recent years, the demand for Flexible Printed Circuit Boards (Flex PCBs) has surged across multiple industries, thanks to their lightweight, space-saving design and superior performance. A report by Smithers Pira indicates that the global PCB market is projected to exceed $80 billion by 2025, with the demand for Flex PCBs accounting for a significant share, driven primarily by the consumer electronics and automotive sectors. Companies like Apple and Tesla have effectively implemented Flex PCB assemblies to streamline production processes and enhance product functionality, showcasing the adaptability of these circuits in complex designs.

The medical device industry is another key player benefiting from Flex PCB technology. According to a study by the American Institute for Medical and Biological Engineering, the integration of flexible electronics in medical devices has improved diagnostics and reduced patients' discomfort. Notably, devices such as wearable health monitors now feature advanced Flex PCBs that accommodate multiple sensors and functionalities while maintaining a compact design. Such successful global implementations highlight the versatility and effectiveness of Flex PCB assemblies in addressing diverse industry needs, reaffirming their pivotal role in the future of electronics manufacturing.