How to Ensure Quality in Best Flex PCB Assembly Processes

In today's rapidly evolving electronics industry, ensuring the quality of flex PCB assembly processes is paramount for manufacturers aiming to stay competitive. As flexible printed circuit boards (PCBs) become increasingly integral in various applications, from consumer electronics to medical devices, the demand for high-quality assembly practices surges. Import and export certifications play a crucial role in this landscape, providing a framework that not only guarantees adherence to international standards but also fosters trust among stakeholders. This blog explores the significance of these certifications in relation to flex PCB assembly, outlining the best practices that manufacturers should adopt to ensure compliance and enhance product quality. By understanding the intricacies of certification processes, businesses can better position themselves in the global market, reduce risks, and ultimately deliver superior products that meet customer expectations.

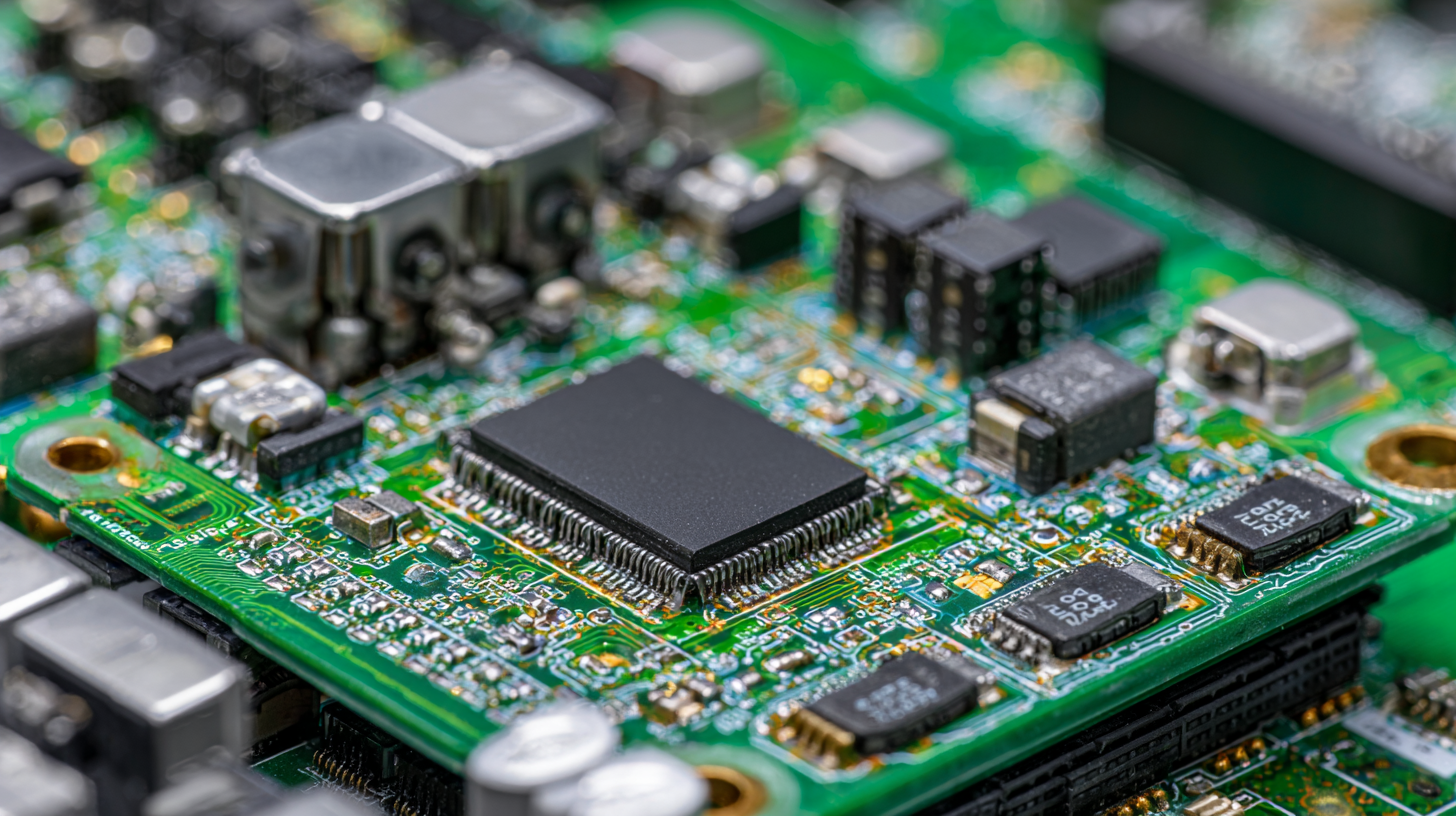

Understanding the Importance of Quality Standards in Flex PCB Assembly

In the realm of flexible PCB assembly, understanding the significance of quality standards is crucial for ensuring reliability and performance. Recent advancements in lean manufacturing focus on enhancing quality and efficiency across production systems, which is particularly pertinent as the PCB industry marches towards higher complexity.

According to the industry outlook, the Printed Circuit Board Assembly market is projected to reach USD 55.33 billion by 2034, highlighting the increasing demand for high-quality assemblies developed under stringent quality standards.

With the rapid advancement in technologies like 5G, manufacturers face new challenges in designing high-frequency PCs that require precise pattern designs and innovative materials. The necessity for traceability in PCB designs, coupled with improvements in manufacturing processes, ensures accurate identification and tracking of components throughout the assembly lifecycle. This structured approach not only mitigates errors but also upholds industry standards, ultimately fostering greater consumer confidence in flexible PCB products.

As the sector evolves, adhering to established quality standards will be pivotal for manufacturers aiming to remain competitive in this dynamic market.

Key Industry Certifications and Their Impact on Flex PCB Quality

In the rapidly evolving landscape of electronic manufacturing services, ensuring quality in flexible printed circuit board (Flex PCB) assembly is paramount. The global market for PCBs is anticipated to grow significantly, reaching approximately USD 139.63 billion by 2032, driven in large part by increasing smartphone adoption and innovative technologies. This growth emphasizes the importance of adhering to strict quality standards and obtaining key industry certifications, which directly impact the reliability and durability of Flex PCBs.

Industry certifications such as ISO 9001 and IPC-A-610 play a vital role in maintaining high quality throughout the PCB assembly process. Companies that invest in these certifications not only enhance their product quality but also gain a competitive advantage in a burgeoning market that is expected to see a compound annual growth rate (CAGR) of 6.9%, propelling the electronic manufacturing services sector from USD 648.11 billion in 2025 to USD 1,033.17 billion by 2032. As innovations continue to drive the industry forward, manufacturers that prioritize these quality parameters will be better positioned to meet the increasing demand for reliable and efficient electronic components.

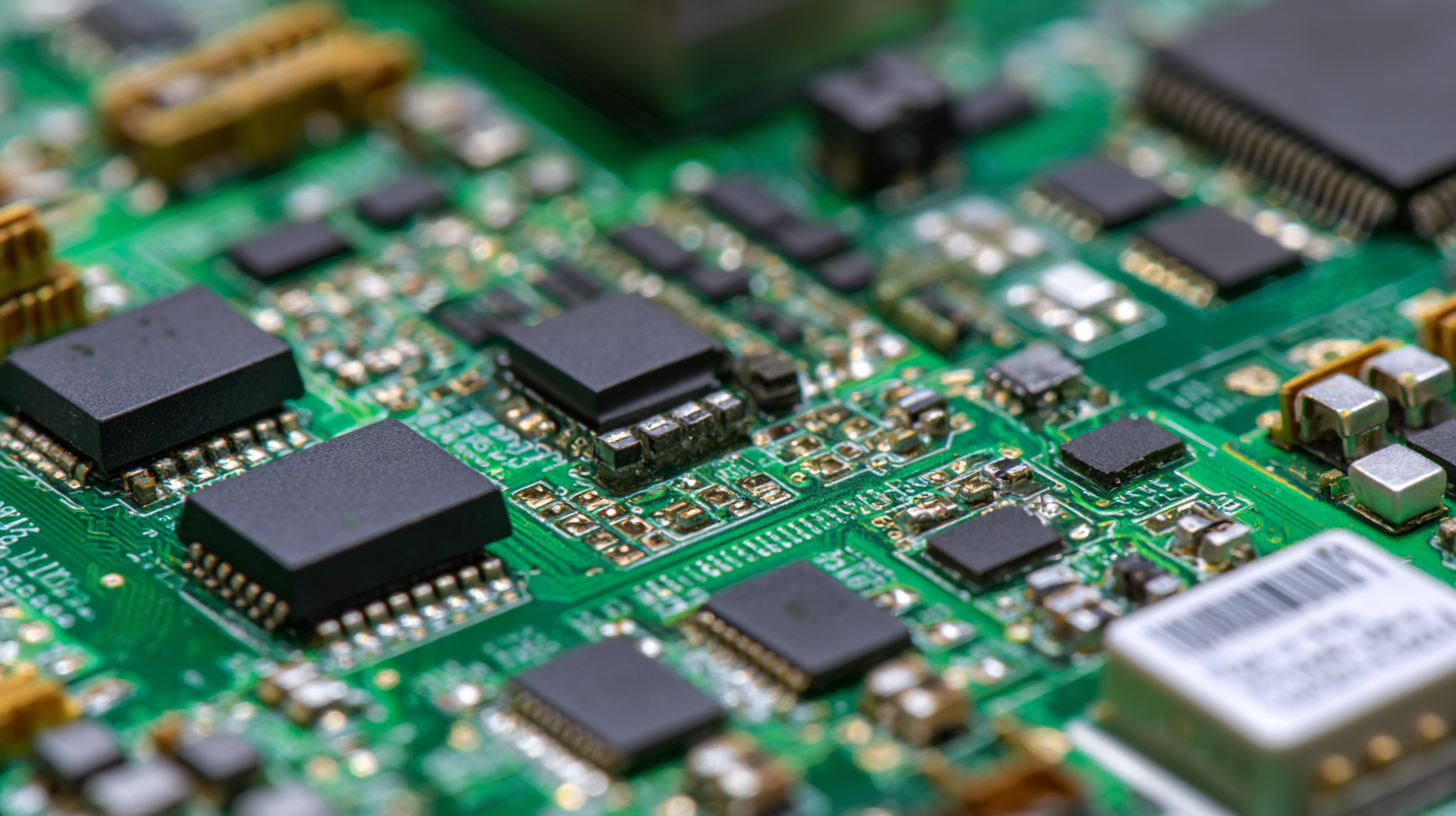

Best Practices for Selecting High-Quality Materials in Flex PCB Production

When it comes to flex PCB production, the choice of materials is paramount to ensuring quality and performance. High-quality materials not only enhance the durability and flexibility of the printed circuit boards but also contribute significantly to the overall functionality of the electronic devices they inhabit. When selecting materials for your flex PCB assembly, it’s essential to consider factors such as thermal properties, dielectric strength, and mechanical endurance. For instance, Polyimide films are widely recognized for their excellent thermal stability and flexibility, making them ideal for demanding applications.

Another crucial consideration in material selection is the copper thickness used in the flex PCB. Choosing the right copper weight is vital for ensuring optimal conductivity and reliability. Additionally, using high-grade solder masks and surface finishes can enhance the longevity and performance of the flex circuits. When sourcing materials, look for reputable suppliers that adhere to stringent quality standards, ensuring that you receive components that will perform well under stress. By prioritizing high-quality materials in your production process, you can significantly improve the overall reliability and efficiency of your flex PCBs.

Quality in Flex PCB Assembly Processes

This chart presents the importance of selecting high-quality materials in the Flex PCB production process, highlighting the average defect rates associated with different material quality levels.

Effective Testing Methods to Ensure Flex PCB Reliability and Performance

In today's fast-evolving electronics landscape, ensuring the reliability and performance of flexible PCBs (Printed Circuit Boards) is crucial. With the growing prevalence of flex PCBs in fields such as wearable technology and automotive applications, implementing effective testing methods becomes vital. According to a report by the IPC (Institute for Interconnecting and Packaging Electronics), over 30% of PCB failures can be attributed to inadequate testing processes, underscoring the need for rigorous quality assurance protocols.

One key strategy in testing flex PCBs involves mechanical stress testing, allowing manufacturers to assess how the boards respond to bending and twisting. It's essential that these tests simulate real-world scenarios, ensuring the PCB's durability under daily use. Additionally, incorporating electrical testing such as in-circuit testing (ICT) helps identify faults early in the assembly process, reducing the risk of failures down the line.

**Tip 1:** Implement automated optical inspection (AOI) systems to enhance precision in detecting defects that might go unnoticed to the human eye.

**Tip 2:** Regularly conduct thermal cycling tests to ensure that flex PCBs can withstand extreme temperature variations, which is critical for performance longevity in diverse environments.

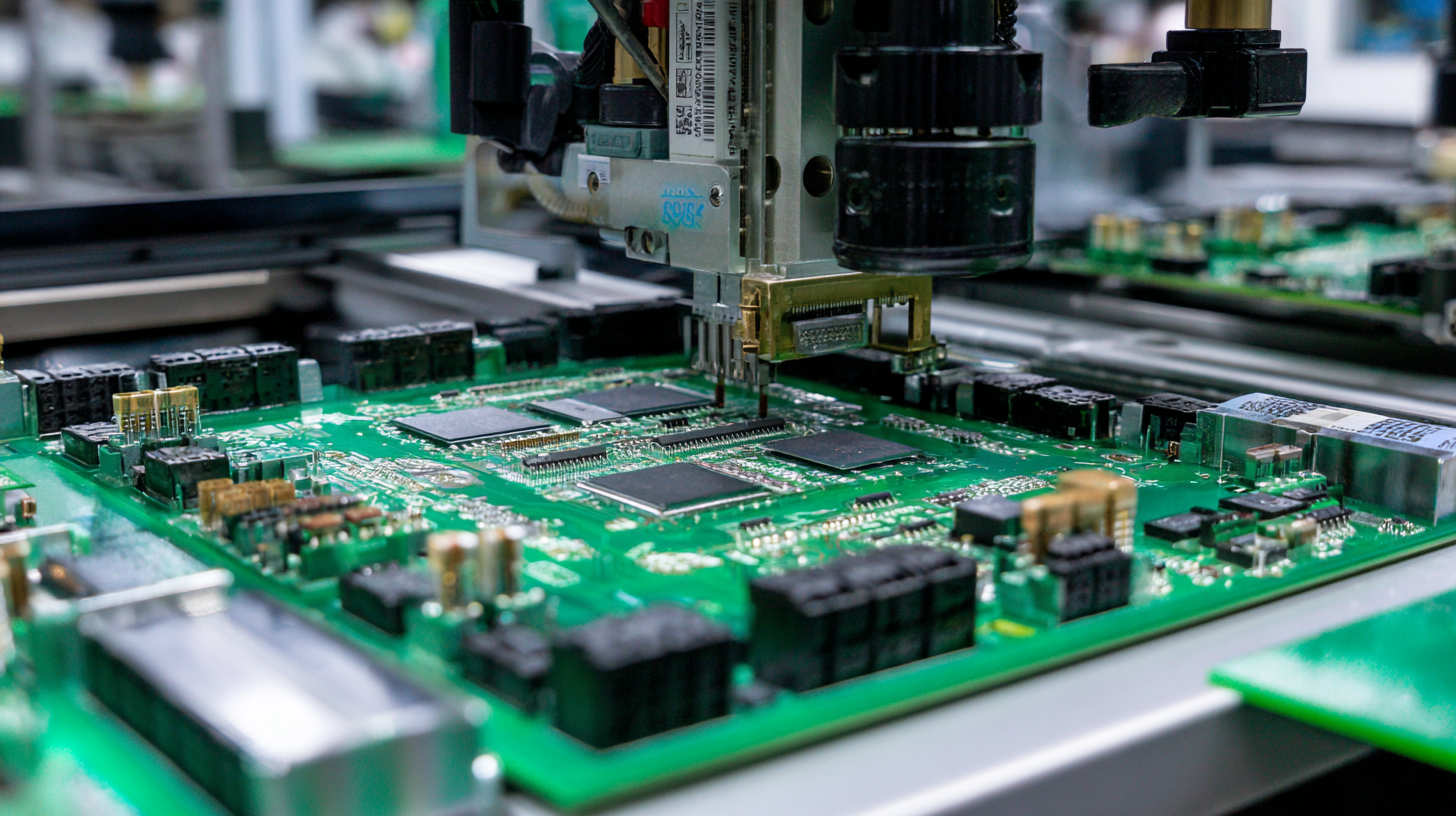

Continuous Improvement Strategies for Optimizing Flex PCB Assembly Processes

Continuous improvement strategies are essential in optimizing flex PCB assembly processes to ensure high quality and efficiency. According to a recent industry report by IPC, a global association representing the electronics manufacturing industry, process defects account for approximately 30% of production waste in PCB assembly. Implementing Lean manufacturing principles can significantly reduce this waste by streamlining processes and enhancing quality control. By prioritizing these methodologies, companies can achieve a remarkable reduction in defect rates and ultimately lead to faster turnaround times.

Moreover, fostering a culture of continuous feedback is critical in refining flex PCB assembly. Research from the Institute of Printed Circuits highlights that companies adopting regular performance evaluations and employee input have improved process efficiency by 25%. Integrating advanced technologies such as automated inspection systems and real-time monitoring can also support these initiatives by providing immediate data on assembly performance. This data-driven approach allows teams to identify bottlenecks and implement corrective actions swiftly, ensuring that quality standards are consistently met throughout the production cycle.