Top 10 Tips for Effective Printed Circuit Board Assembly in Electronics

In the rapidly evolving field of electronics, effective printed circuit board assembly (PCBA) is crucial for ensuring the reliability and performance of various devices. According to industry expert Dr. Maria Chen, “The precision in printed circuit board assembly can make or break the functionality of electronic products, emphasizing the need for best practices and attention to detail.” As the backbone of electronic systems, printed circuit boards must be assembled with the utmost care to avoid costly failures and ensure optimal operation.

With technology continuing to advance, the complexity of printed circuit board assembly has also increased, requiring manufacturers to adopt innovative techniques and rigorous quality control measures. The integration of automation and state-of-the-art tools plays a pivotal role in enhancing the speed and accuracy of the assembly process, ultimately leading to improved product quality. In this article, we will explore the top 10 tips for effective printed circuit board assembly, drawing on insights from industry leaders and highlighting best practices that can streamline production and reduce errors.

By adhering to these essential guidelines, manufacturers can enhance their PCBA processes, ensure compliance with industry standards, and deliver high-performance electronic products that meet the increasing demands of consumers.

Understanding the Basics of Printed Circuit Board (PCB) Assembly

Understanding the basics of Printed Circuit Board (PCB) assembly is crucial for anyone involved in electronics manufacturing. This process transforms a conceptual electronic design into a functional product by incorporating various electrical components onto a PCB. According to a report by the IPC (Institute for Printed Circuits), the global PCB market is expected to reach a value of approximately $90 billion by 2025, driven primarily by advancements in technology and increased demand for electronics in sectors like automotive and consumer goods.

At the heart of PCB assembly are essential processes like surface mount technology (SMT) and through-hole technology, which enable efficient and reliable component placement. A study from the Electronics Industry Association indicates that SMT is now the dominant assembly method, accounting for over 75% of PCB production due to its ability to facilitate higher density and more compact designs. Understanding the intricacies of these methods, along with proper soldering techniques and quality control measures, is vital for ensuring the longevity and performance of electronic devices. Properly executed PCB assembly can significantly impact the failure rates of electronic products, ultimately influencing customer satisfaction and brand reputation in a highly competitive market.

Top 10 Tips for Effective Printed Circuit Board Assembly in Electronics

| Tip Number | Tip Description | Importance |

|---|---|---|

| 1 | Design for Manufacturability (DFM) | High |

| 2 | Select the Right Materials | High |

| 3 | Utilize Automated Processes | Medium |

| 4 | Implement Quality Control Checks | High |

| 5 | Choose the Right Soldering Techniques | High |

| 6 | Plan for Thermal Management | Medium |

| 7 | Minimize Signal Integrity Issues | High |

| 8 | Optimize PCB Layout | High |

| 9 | Ensure Component Placement Accuracy | Medium |

| 10 | Perform Final Testing and Validation | High |

Selecting the Right Materials for PCB Assembly

Selecting the right materials for printed circuit board (PCB) assembly is crucial for ensuring longevity, reliability, and performance in electronic devices. The choice of substrate materials, such as FR-4, which offers a good balance of electrical insulation and thermal performance, is often the first step. Additionally, considering specific environmental factors can determine if more specialized materials like polyimides or PTFE are necessary. These materials can withstand extreme temperatures and harsh conditions, ensuring that the PCB operates efficiently under various circumstances.

Furthermore, the selection of solder materials plays a vital role in the assembly process. Lead-free solder options are now prevalent, aligning with environmental regulations while providing reliable conductivity. Evaluating the thermal and mechanical properties of different solder types can prevent issues like cold solder joints and ensure strong electrical connections. Additionally, components with compatible thermal expansion characteristics should be chosen to minimize stress on the PCB during operation. By carefully selecting these materials, manufacturers can enhance the performance and lifespan of their electronic products, ultimately leading to increased consumer satisfaction.

Essential Tools and Equipment for Efficient PCB Assembly

In the realm of electronics, efficient PCB assembly relies heavily on the right tools and equipment. Essential items include soldering stations, PCB milling machines, and pick-and-place machines. A high-quality soldering station is crucial for making precise connections, while milling machines allow for the modification of PCB layouts to accommodate specific designs or components. Pick-and-place machines enhance efficiency, allowing for quick and accurate placement of components on the board.

When assembling PCBs, one critical tip is to ensure proper workspace organization. Keeping tools and components neatly arranged can significantly reduce assembly time and minimize errors. Another important tip is to regularly maintain and calibrate your tools. Well-maintained equipment ensures better performance and higher quality in the final product. Additionally, investing in a good inspection tool, such as a microscope or magnifier, can help catch potential issues early in the assembly process, preventing costly mistakes down the line.

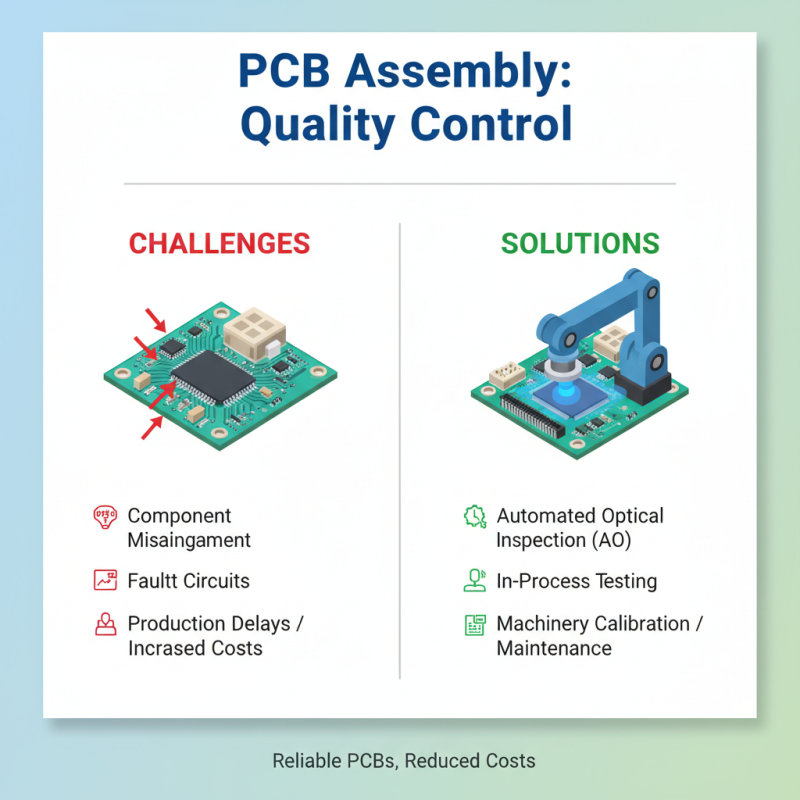

Quality Control Practices in PCB Assembly Process

Quality control is a critical aspect of the printed circuit board (PCB) assembly process, ensuring that the final product meets stringent industry standards and customer expectations. According to a 2023 IPC report, improper assembly practices can lead to defects and failures in up to 30% of manufactured boards, emphasizing the need for effective quality control measures. Implementing systematic inspections at various stages of the assembly process can significantly mitigate these risks.

One essential tip for enhancing quality control in PCB assembly is to conduct regular automated optical inspections (AOI). This technique allows for real-time detection of defects like misaligned components or solder defects, enabling quick corrections before further production stages. Furthermore, establishing a robust training program for assembly line workers can enhance their ability to identify potential issues early on, leading to reduced rework costs and improved product reliability.

Additionally, embracing statistical process control (SPC) can be a game-changer in maintaining consistent quality levels. By analyzing production data, manufacturers can assess variances from specified tolerances and implement corrective actions proactively. Continuous monitoring and data analysis not only enhance the quality of PCBs but also improve overall operational efficiency, reducing waste and manufacturing costs in the long run.

Top 10 Quality Control Practices in PCB Assembly

Common Challenges in PCB Assembly and How to Overcome Them

In the world of printed circuit board (PCB) assembly, numerous challenges can arise during the manufacturing process, leading to delays and increased costs. One of the most common issues is the misalignment of components, which can result in faulty circuits and malfunctions. To overcome this, it is crucial to implement rigorous quality control measures, including the use of automated optical inspection (AOI) and testing at various stages of assembly. Regular calibration and maintenance of machinery will also ensure that components are placed accurately, ultimately reducing the risk of misalignment.

Another significant challenge in PCB assembly is the selection of materials. A mismatch between components and the chosen substrate can lead to reliability issues in the final product. To mitigate this risk, thorough research and compatibility testing should be conducted before the assembly process begins. Collaborating with material suppliers and staying updated on industry standards can enhance decision-making, ensuring that all materials used are suitable for the application. Additionally, maintaining clear communication between design engineers and assembly teams will help identify potential material-related concerns early in the process, allowing for timely adjustments and improved outcomes.

Related Posts

-

Navigating the Future of Best Printed Circuit Board Assembly in the 2025 Market Landscape

-

Challenges with Achieving Best PCB Printing Quality

-

Navigating the 2025 PCB Design and Assembly Trends for Global Buyers

-

Exploring Innovative Alternatives in PCB Design and Assembly for Global Buyers

-

Ultimate Guide to Choosing the Right PCBA Manufacturing Partner for Global Procurement

-

Exploring Sustainable Circuit Board Manufacturing Alternatives for Eco-Friendly Solutions

MSIRobot